Friction stir welding

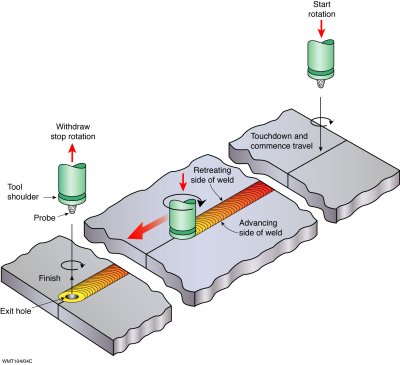

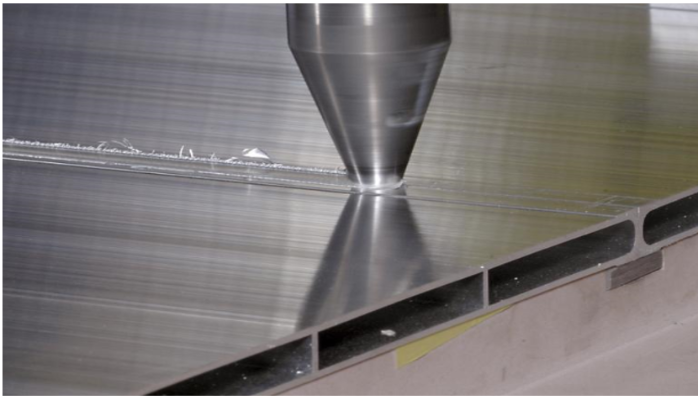

Friction Stir Welding is an attractive technology for material joining. Contrary to conventional welding methods, friction welding has the ability to produce welds with higher integrity and minimum induced distortion and residual stress.

In contrast to conventional welding techniques, FSW requires no filler material, gas or other consumables - and consumes much less energy. It generates no harmful gases, no slag, no spatter and little sound, the process actively contributes to a better working environment, while simultaneously boosting productivity. The weld strength quality is excellent.

FSW allows to develop new applications by its unique benefits. It is possible to join materials which were previously impossible, like high strength aluminum alloys (2xxx and 7xxx series), as well as joining of dissimilar materials.

Benefits of FSW

- No joint preparation

- High quality welds

- Environment friendly : no arc, welding fumes or spatter

- Low operational cost : no consumables and low energy costs

- No post-weld treatment

- Low distortion and shrinkage

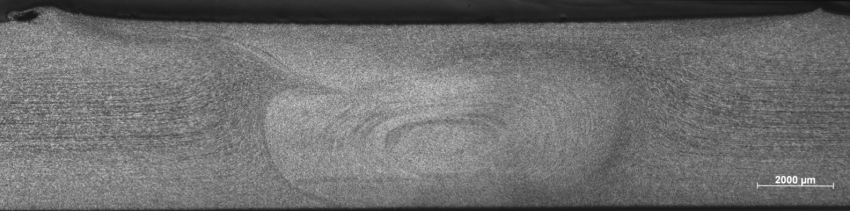

Feasibility investigation

BWI can assess the feasibility of this process for your materials or applications. Through our partner network, we can also carry out welding trials with subsequent full weld characterisation. For further questions, please contact Koen Faes