MICROSOUD: Micro-welding platform in Wallonia

Micro welding and associated quality control

The BWI (Belgian Welding Institute) works in collaboration with CEWAC (Centre d’études wallon de l’assemblage et du contrôle des matériaux) and MULTITEL, 2 other approved research centers on a huge project concerning micro welding and associated quality controls. The application of this project is done within the frame work of the first call of the FEDER project 2007-2013. It has started on July 2008.

To start with, at CEWAC, a platform that groups different mico welding processes and adapted, advanced quality controls has to be build up. The technologies are: micro-friction stir welding, micro-plasma, micro-TIG, micro-resistance welding, micro-laser welding, micro-electron beam welding, digital micro-radiography and micro-control via adapted penetrant inspection.

Project goals

This platform is open for all companies that are interested in it. By participation in this research project :

- Companies will get an insight in the possibilities of micro-welding and associated quality controls.

- They will be able to assess if these processes are usable for their specific applications, taking into account the joint properties, the necessary investments, the profit increase in comparison with the current applied technique, the reliability of the processes, and so on…

- The participants will have the possibility to steer the project, in function of the needs of their company.

Project description

The different projects are described more in detail.

Project « MICROSOUD »

Collaboration CEWAC and BWI.

This project is about the establishing of a technological platform about ‘micro welding and adapted, advanced controls’. This will be developed under strong accreditations (for aerospace, aircraft, medical world...). This platform has to give service and knowledge of the modern technology of micro welding and associated quality control to the companies, and more specific to the SME’s. This will allow them to use these technologies in the creation and realization of innovative products/services (taylor-made pre-series) and/or to adapt their existing, less competitive product.

The goal is to introduce these technologies more easily in the companies by:

- Sensitization and

- Collecting practice technological expertise

- Training, application specific to the company

- Capacity to realize small series at CEWAC,

following the strong standards and accreditations. So, companies should easily get introduced in the new market and have insight in the technology, accreditation, profitability, environment and training of their human resources.

The project is focused on the advanced technologies such as: micro friction stir welding*, micro-plasma, micro-TIG, micro-resistance welding, micro-laser welding*, micro-electron beam welding*. The technologies indicated with * will be bought within this project; the others are currently available at CEWAC.

Also the associated quality controls such as digital micro-radiography and micro-control with adapted penetrant inspection will be available. These are very cost-effective techniques, which are at the same time difficult to access and which mean an investment as well for purchase as for the training of the people as for the knowledge of the accreditation and standards in the domains of micro mechanics, aircraft, aerospace, medical, electromechanics, transport, security,…

This project fits completely in the further development of the research centers CEWAC and BWI, who work closely together since the signature of a scientific collaboration in 2005.

|

Al-Cu joint by electron beam welding (FOCUS) |

Membrane: CrNi-Foil (50 μm) in between 2 stainless steel rings, welded by electron beam (FOCUS) |

|

2 welded Nitinol wires - wire diameter : 0.38 mm |

Laser micro welding of Cu and stainless steel (0,25mm) |

|

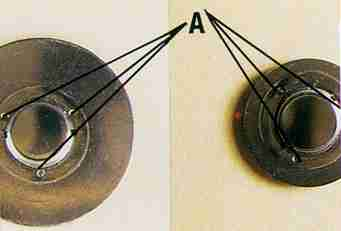

NiMH Battery Caps - resistance welding (Unitek Miyachi Corporation) |

|

Project « Laser NDT »

Collective research project between the approved research centers CEWAC and MULTITEL

This project ‘laser NDT’ wants to introduce and develop the technology of mico laser welding in the companies and at the same time, wants to miniaturize existing components. This project is focused on the development of specific control methods for micro laser welding (so it can be seen as a more in-depth study of the previous project).

The industrial development of the laser technology requires a qualitative non-destructive control usable in the production line. This can reduce the cost and avoids also the production of wasted products. Taking into account the small joints and the small thicknesses, the classical non-destructive tests are not appropriate, with the exception of radiography. The radiography is at the moment less profitable for a continuous industrial project, due to his cost, the difficulty of interpretation, the application after the welding and so on.

The goal of this project is to study and validate an innovative method for quality control which can be used in a continuous process of micro welding, in other words, an automatic system of in-line quality control. The system will exist of signal acquisition, filtering and analysis which will be compared to reference signals and as result will send an alarm in case of inacceptable failure.

Project « INTROTECH PME »

Optimalisation of the offered, technological services by the approved research centers.

This project consists of the offer of technological services (information, dissipation, technological transfer) which give an answer to the needs concerning establishing, development and/or reinforcement of the companies, and more specific the Walloons SME’s and SE’s. This has to allow to introduce innovative technologies of welding and quality control in the production, mainly of metals. This makes the company able to improve the competitively, productivity and/or the quality of the production.

The micro-assembly technologies such as laser, electron beam welding, friction stir welding, micro-TIG, micro-plasma, radiography, … will be valorized.

This platform MICROSOUD will also support the build-up of a network of competitive SME’s in the domain of micro-assemblies and micro-controls. They will have access to similar technologies which will improve and accelerate the dissipation and the transfer of technology, in the direction of the SME’s, as well as in the direction of technology centers and training centers.