Acoustic emission measurement system

Quality control via acoustic emission as a non-destructive and comparative test method is developed based on the fact that each material exhibits natural vibrations and that machines and processes emit sounds. During the creation of a weld, acoustic emissions are created, due to the formation of the weld, the emergence of defects or disturbing influences. The form in which acoustic emission occurs depends on the welding process, the material, the temperature and the geometry of the workpiece. The fundamental objective of monitoring via acoustic emissions during welding is to obtain useful information about the weld quality and the suitability of the welding parameters used during welding. By using the correct equipment and settings and the accompanying analysis software, the various sources of acoustic emission can be distinguished and possible welding defects can be demonstrated.

|

|

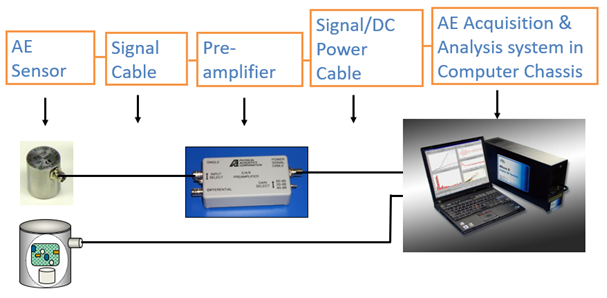

Set-up of the acoustic emission system |

|

|

Acoustic emission measurement set-up for friction spot welding |