Friction spot welding of aluminium alloys : Weldability and mechanical properties

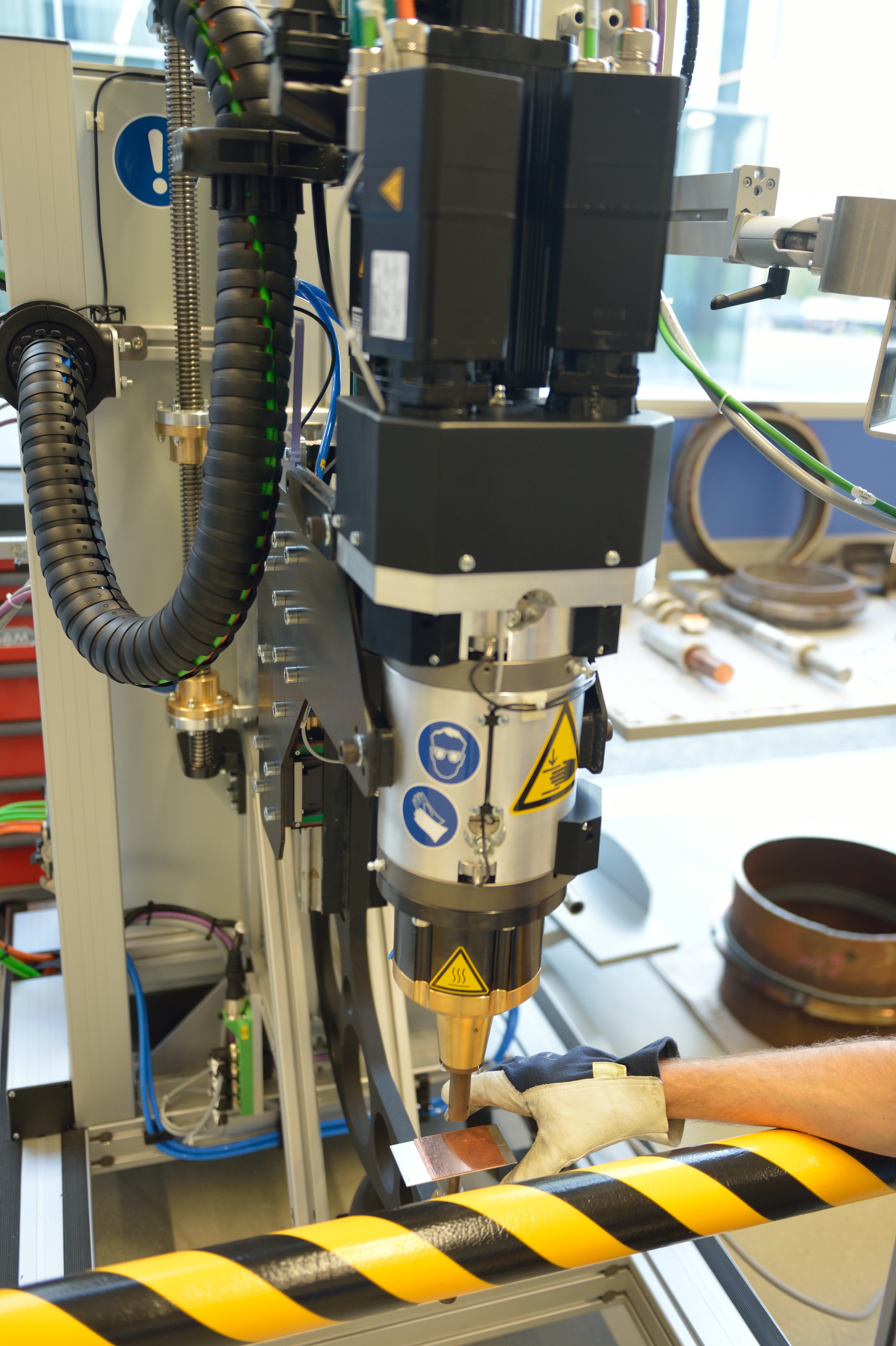

Friction spot welding

- click here for more information about the process.

Advantages of the process

- ideal for welding aluminium,

- offers a solution to the problems of the resistance spot welding of aluminium alloys,

- welding of advanced higher-strength aluminium alloys is possible, which are not weldable with conventional welding techniques,

- welding of dissimilar materials, such as aluminium-steel, coated aluminium alloys, or materials with unequal thicknesses,

- short welding time,

- ecological process: no filler materials or protective gases are used and there are no welding fumes, IR-, UV- or electromagnetic radiation.

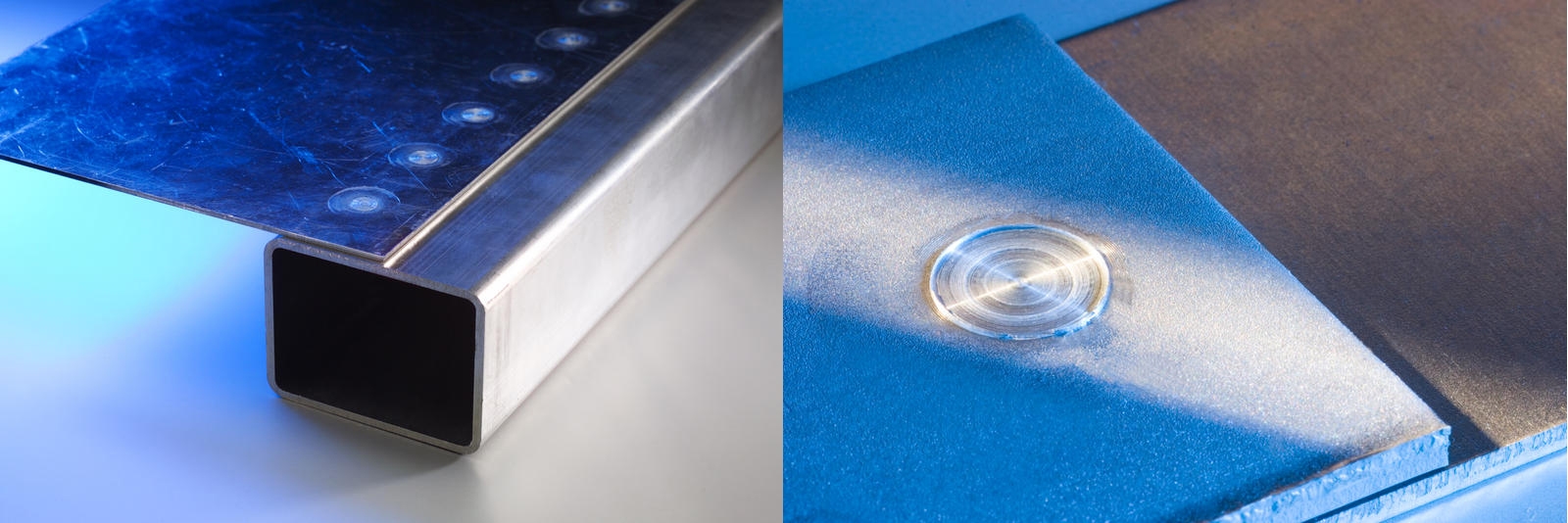

Friction spot weld of aluminium

Friction spot weld of aluminium and galvanised steel

Friction spot weld of aluminium and copper

Project goals

Standards

The increasing use of the friction spot welding process has created the need for a standard to ensure that the welding is performed in the most effective manner and that appropriate controls are exercised on all aspects of the implementation.

A practical process qualification method for friction spot welding is under development and is described in ISO FDIS 18785. This international standard focuses on the friction spot welding of aluminum, since most commercial applications for friction spot welding were realized for aluminum at the time this standard was developed. Examples are the rolling stock for railway applications, consumer products, processing equipment for the food industry, automotive parts, aerospace and marine applications.

Pre-normative purpose

The main objective of the research project is to generate data regarding acceptance criteria for destructive testing, parameter settings, mechanical properties, geometric characteristics, welding procedures and test recommendations for friction spot welds, as input for the ISO / CEN standard.

It will help to further spread of this innovative technology and will lower the threshold for the implementation of this innovative welding technique in industry.

Specific goals

Through an experimental study of a wide variety of aluminum alloys, technical data will be generated that will serve as input for the ISO / CEN standard:

- parameter data and machine settings for high-quality welding of the selected alloys and / or material combinations and for the thicknesses examined.

- generating data regarding the mechanical properties of friction spot welds,

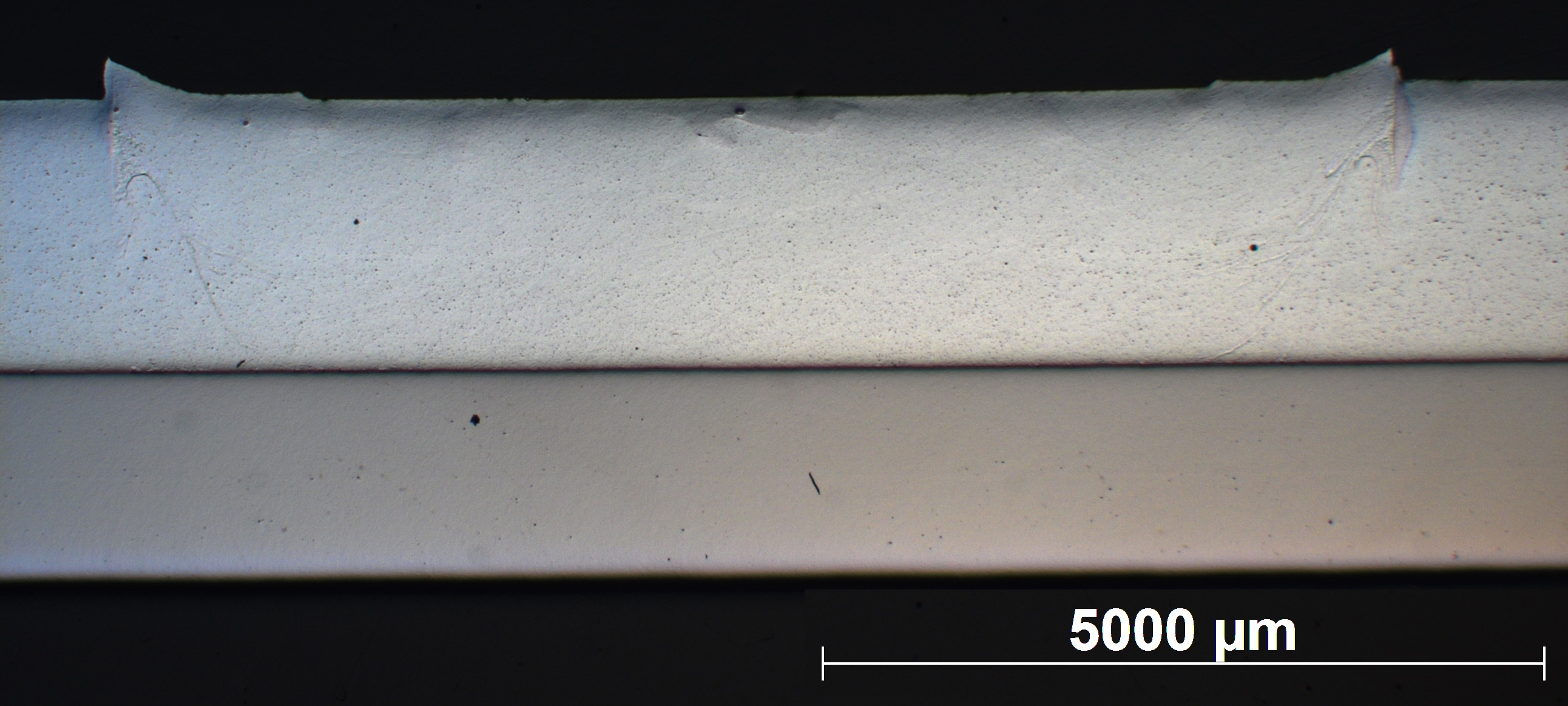

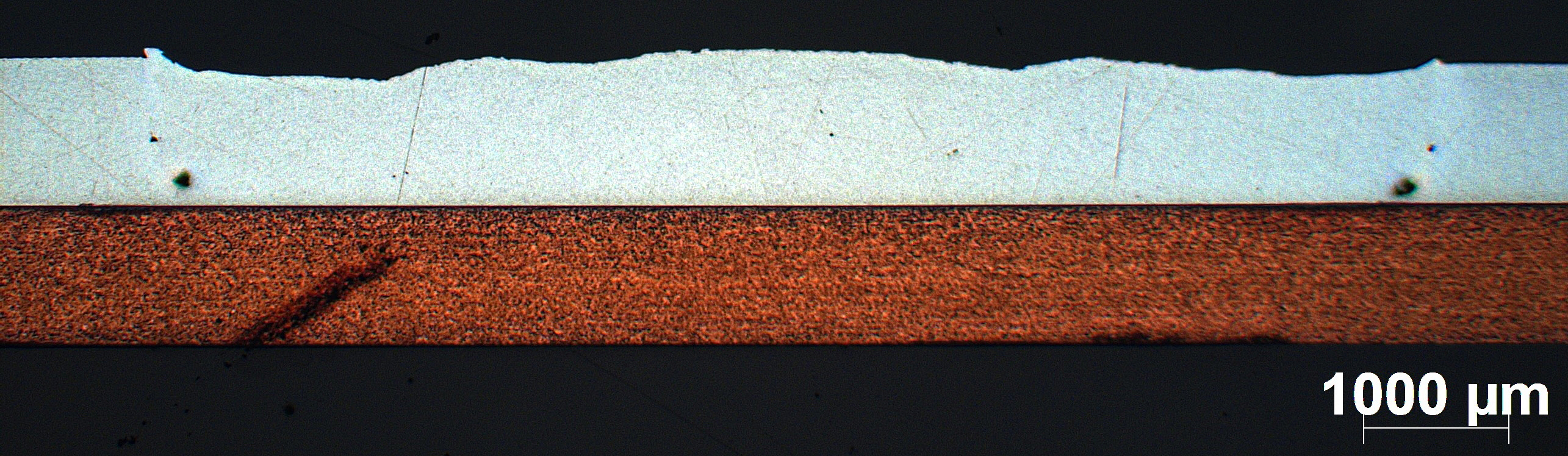

- geometric features of the weld,

- welding procedure for each material examined, material combination and thickness,

- recommendations on the minimum tests to be carried out,

- the minimum quality requirements for the materials and thicknesses examined.

This will be included in a technical report that will be referred to from the ISO FDIS 18785 standard; the standard in development for friction spot welding.

An additional aim of the project is to formulate adaptations for a number of standards, such as ISO FDIS 18785-4, ISO FDIS 18785-5, EN 1090-3 and Eurocode 9.