HYBRISONIC: Ultrasonic supported processing of hybrid materials

Aluminium-composite sheets

Aluminium-composite sheets have many advantages compared to other materials. Thanks to the use of aluminium and plastic, the plates are lightweight and stiff. Because aluminium sandwich panels can be easily and economically manipulated with simple tools, the material offers a tremendous form of freedom. Another advantage is that the plates are fire-retardant or sometimes even fire-resistant. Finally, they are also durable because they are completely recyclable.

Aluminium-composite sheets can be used for a wide variety of applications. In construction, the panels are often used as façade sidings, but they can also serve as machine shielding or roofs. Aluminium-composite panels can be used for flat facade sidings and interior applications. They are lightweight, extremely stiff and completely flat. Acoustic comfort combined with a high weather resistance, thermal and fireproof quality are the reasons why this product is used a lot in the construction industry.

Ceiling in aluminium-composite panels for acoustic insulation

Application for the production of the frame of lightweight benches for trains

Steel-composite sheets

Metal-composite sandwich panels play an increasingly important role for lightweight design and for reducing noise and vibrations in the transport sector. To achieve the EU's emissions targets, economic lightweight concepts play an important role for the transport and automotive industries. Developers, manufacturers and suppliers use steel-composite panels, which are lighter than the monolithic steel components and cheaper than the aluminium components.

By using these materials, a weight saving of 10% can be achieved, while maintaining the production infrastructure.

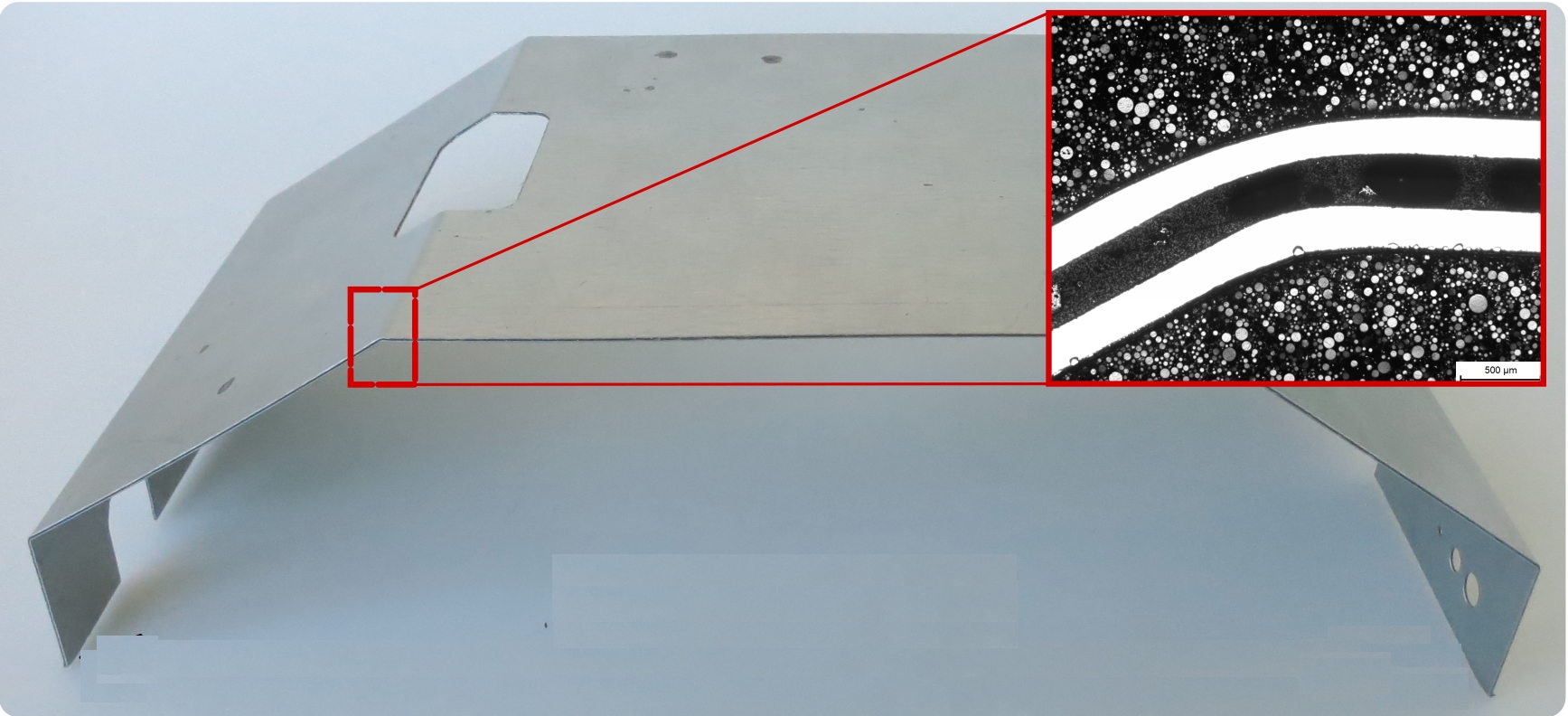

Machine casing

Project goals

Challenges

The use of these hybrid materials poses challenges for the joining technology. The first requirement for the use of such hybrid components is the availability of suitable joining techniques. Different combinations in terms of materials and thicknesses complicates the robust joining of these materials even more.

Because of the intermediate layer (e.g. polymer), processing of these hybrid materials is difficult in many aspects and new approaches are required. One of the most commonly used connection techniques for sheet materials is resistance spot welding. On the one hand, the intermediate layer acts as an electrically insulating barrier, so resistance welding is not possible. On the other hand, the difference between the mechanical properties of the composite layer and the metal cover is large, leading to further restrictions for the application of processing techniques.

Recent developments have taken place for a number of joining processes. New hybrid joining techniques have been developed. The possibilities and limitations of these techniques must be known to allow companies to use them for manufacturing of multi-material components using sandwich materials.

Cross-section of a riveted connection of a metal-composite sandwich plate

Cross-section of a clinched connection of a metal-composite sandwich plate

Project description

Collective research!

The Belgian Welding Institute has started a research project about joining of sandwich materials. Several hybrid connection techniques will be developed and tested on different materials. The project focuses on 4 connection techniques; more specifically clinching, riveting, resistance welding and friction spot welding.

To ensure that the sandwich plates can be connected with these techniques, the plastic core must be displaced locally. In the planned project, 2 concepts for the displacement of the plastic core were examined.

The first concept is the development of a hybrid joining technique, in particular a combination of ultrasonic welding and clinching or resistance welding. For this concept, a sonotrode for generating the ultrasonic vibrations was integrated into the joining tools. Through the ultrasonic vibrations, the plastic core of the sandwich plate were displaced so that the plates can be joined. A second approach also uses ultrasonic vibrations to displace the plastic core, but as a preliminary step. Afterwards, the treated plates can be connected with riveting or friction spot welding.

In addition, industrial case studies will be developed to demonstrate the potential of the new processes.

Friction spot welding machine

Results

- Publication : Novel Ultrasonic-Based Joining Methods for Metal-Plastic Composites (MPC)

- Publication : Joining Of Metal-Plastic Composites With Advanced Welding Processes

- Publication : Ultrasonic supported Resistant Spot Welding for Metal-Plastic Composites

- Publication : Development of Resistance Spot Welding Processes of Metal–Plastic Composites

Read more

- INNOJOIN: Development and evaluation of advanced welding technologies for multi-material design with dissimilar sheet metals

- Join'EM: Joining of copper to aluminium by electromagnetic fields

- MetalMorphosis : Electromagnetic pulse technology for novel hybrid metal-composite components in the automotive industry

- SOUDIMMA : Electromagnetic pulse welding