WAALU : 3D WAAM printing of high-strength aluminium alloys

Project goals

The WAALU project aims to overcome the scientific and technological obstacles for the use of 7xxx series aluminium alloys with the WAAM technology. Particular attention will be paid to the hot cracking sensitivity (choice and modification of alloys), as well as to WAAM fabrication strategies and (welding) process parameters.

The research team also intends to study and optimise the sequence of post-treatments (post weld heat treatment and/or surface finishing) required to ensure the best performance of the manufactured parts.

The final result to be achieved will be a methodology for the fabrication/functionalisation of Al 7xxx alloy parts using the WAAM technology.

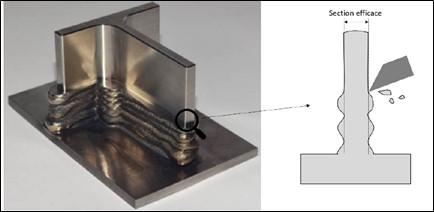

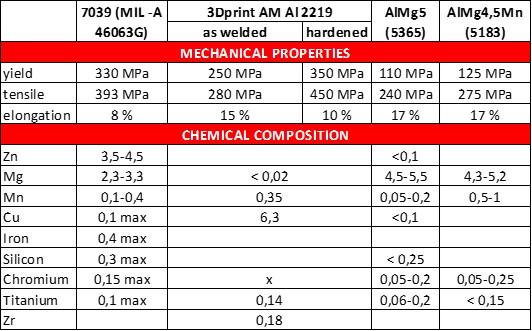

This methodology will be validated using a technological demonstrator, made of aluminium 7xxx and manufactured by WAAM, based on the case study proposed by John Cockerill but with a simplified geometry (part of workpiece and/or at reduced scale). The complete methodology will ensure that the produced parts have mechanical properties which are at least equivalent to those of forged materials (Aluminium 7039).

Results

The specific tasks/objectives for the Belgian Institute of Welding (BWI) within this project are:

- WAAM printing with additive materials: Aluminium 5183, 5356, 2219 (high strength) as well as a high strength aluminium consumable (7000 series) developed by UCL.

- The WAAM prints will be done with:

- KUKA robot + fronius CMT

- COBOT UR10 + megatronic - Printing of a (simplified) demonstration model

- Heat treatment and (surface) finishing