INNOLAS: Cost reduction by using innovative welding processes

Project goals

In the last decades, most of the welding activities has being executed using the conventional GTAW and GMAW welding processes. During the last years, a great number of innovative process variants have appeared on the market. These offer a broad range of new production possibilities. For instance, in some cases (e.g. welding of thin sheets), the conventional GTAW welding can be replaced by a new version of the GMAW process, resulting in a much higher productivity, without weld quality loss. In welding high strength steels, it is possible to control the heat input more effectively, resulting in higher joint quality. Moreover, an appreciable productivity increase is expected when welding materials of higher thicknesses.

These new processes will lower the welding costs and increase productivity, and will speed up product development. These benefits will contribute to the development of products with higher added value or a lower production cost, and thus will reinforcing the competitiveness of the companies.

Project description

Several promising new process variants of the GMAW welding process have recently appeared on the market, better known by their acronyms: T.I.M.E., Rapid Melt, Cold Metal Transfer, ColdArc, Surface Tension Transfer (STT), ForceArc, etc ... Also in the field of GTAW, recently several interesting developments are noticed, for instance the TOPTIG- and A-TIG- welding processes. Moreover, in terms of power sources there are interesting evolutions noticeable. The new electronically regulated power sources yield a more reproducible weld quality and an improved weld appearance. More information about these new variants can be found at our website www.BIL-IBS.be

The efficiency increase by using these new welding processes was demonstrated by means of weld trials with actual products of the participating companies. The weld trials was evaluated according to the applicable standards. By means of an economical analysis, the reduction of welding costs will be calculated.

In a short period of time, the participating companies received insight in the capabilities of the new variants of the conventional welding processes. They were able to judge whether these welding processes are applicable in their own production, taking into account the expected weld properties in comparison with the currently used technique, the process reliability and stability, etc …

Welding processes

The following processes were investigated in the project :

Variants of the GMAW welding process :

- T.I.M.E.- and Rapid-Melt,

- ForceArc,

- STT,

- Cold Metal Transfer (CMT) and ColdArc,

- GMAW with a double pulse,

- ...

Variants of the TIG welding process :

- A-TIG,

- TOPTIG,

- ...

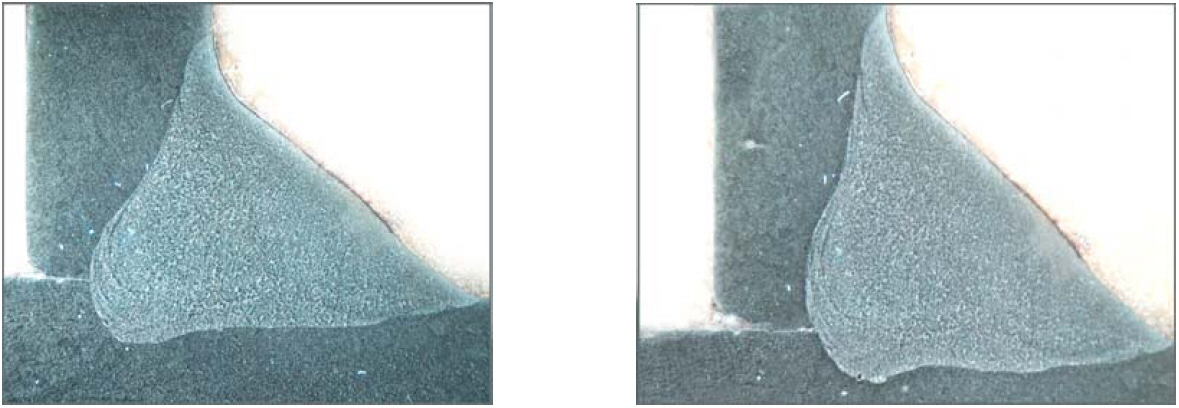

Figure : Comparison between conventional GMAW and Force Arc

Figure : Metal transfer in STT

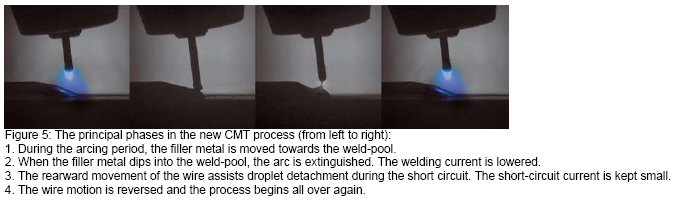

Figure : CMT welding process

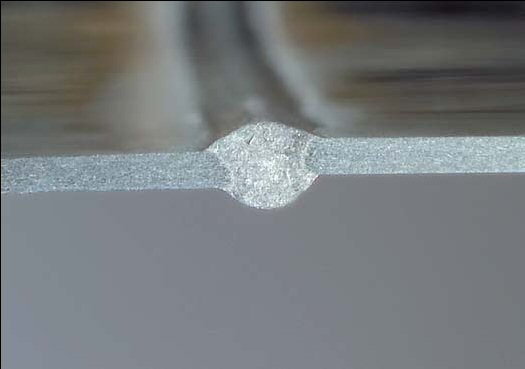

Figure : Butt joint realised with CMT (AlMg3)

Figure : Comparison of TIG and A-TIG

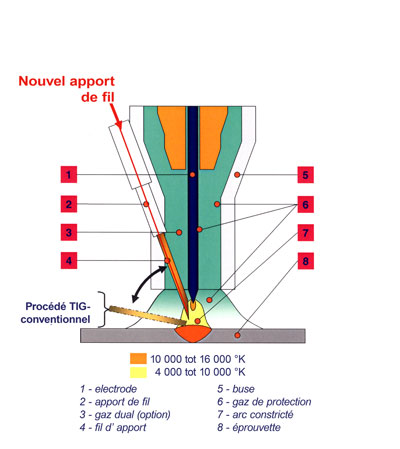

Figure : TOPTIG welding process

Sources

[1] : "Job Knowledge", publié dans "TWI Connect", Janvier 1995.

[2] : "Laskennis opgefrist (nr. 24)", http://www.nil.nl/fris24.htm

[3] : "T.I.ME.-lassen. Deel 1 - Een hoog rendement uit het werkkapitaal." Lastechniek, mars 2006.

[4] : "T.I.M.E.-lassen. Deel 2 - Praktijkvoorbeelden". Lastechniek, avril 2006.

[5] : "ForceArc - Een krachtige variant op het MIG/MAG-lassen". Lastechniek, spetembre 2006.

[6] : "ForceArc - ein kraftvolles Werkzeug zum MIG/MAG-schweissen." DVS Schweisstechnisches Jahrbuch 2005. Site internet

[7] : "Koud en spatloos lassen." De nieuwste ontwikkelingen. Lastechniek, novembre 2005.

[8] : "Recente ontwikkelingen MIG/MAG-lassen." Lastechniek, septembre 2006.

[9] : "Surface Tension Transfer®." www.LincolnElectric.com

[10] : "Cold metal transfer, een revolutie in kortsluitbooglassen". Lastechniek, mars 2005, Theo Luijendijk, TU Delft.

[11] : "Technische en economische evaluatie van lasprocessen voor het verbinden van pijpleidingen bij de firma Denys NV", Ragnar Verhoeven & Christoph Vorsselmans. Case study présenté afin d'obtenir le grade et le diplôme EWE - 2005-2006.

[12] : "The new revolution in digital GMA welding". Fronius Technical Articles.

[13] : "MIG/MAG-lassen met dubbele puls." Hans Wolters, Lastechniek, septembre 2006.

[14] : "MIG/MAG-lassen blijft werkpaard constructeur. Halfautomaat lassen, ontwikkeling en tendensen." Metallerie 52, aout 2003.

[15] : "Basic understanding of A-TIG process". IIW Doc. XII-1802-04.

[16] : "Inventarisatie innovatieve metaalverbindingstechnieken en beheersmaatregelen voor lasrookemissie", TNO-rapport 01M1-01162

[17] : "TOPTIG, een nieuw lasprocédé dat snelheid en hoge kwaliteit doen samengaan." E. Streckx, Air Liquide Welding, Belgium. BIL-Studienamiddag, 18 mei 2006.