AVANGARD – Advanced manufacturing solutions tightly aligned with business needs

The AVANGARD project addresses the integration of three novel processing units into an existing microfactory test bed conceived to produce urban electric vehicles. The units are state of-the-art multipurpose and multifunctional demonstrators on their own, specifically:

- Robotized integration of laser cutting-shaping-welding for 3D components

- Supersonic deposition of metallic powders for high speed 3D printing

- Large volume and high-speed 3D polymeric printing

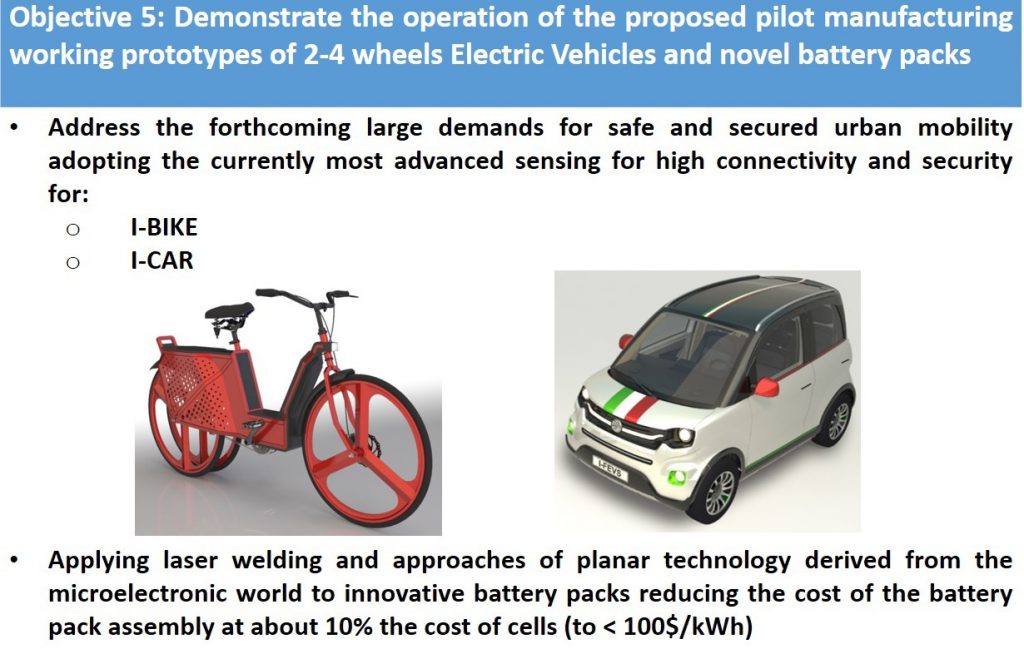

The operation of the AVANGARD pilot will be demonstrated manufacturing I-Bikes, I-CARS and innovative battery packs

Project goals

Het Europese project AVANGARD beoogt de ontwikkeling van een licht en veilig elektrisch voertuig voor personenvervoer in steden. Het project draagt bij tot het gebruik van hoogsterkte staalsoorten door het onderzoek naar en de ontwikkeling van een innovatief chassis voor elektrische voertuigen. Dit moet voldoen aan structurele en veiligheidseisen en zal de ruggengraat vormen voor het ontwerp van een nieuwe generatie elektrische voertuigen met een licht gewicht. Bij deze ontwikkeling worden Dual Phase staalsoorten gebruikt. Dit zijn innovatieve materialen die hun eigenschappen verkrijgen door een unieke structuur bestaande uit twee fasen (ferritisch-martensitische microstructuur).

Objectieven

Project description

Consortium

- PRIMA INDUSTRIE SPA (IT)

- INTERACTIVE FULLY ELECTRICAL VEHICLES SRL (IT)

- MA SPA (IT)

- UNINOVA-INSTITUTO DE DESENVOLVIMENTO DE NOVAS TECNOLOGIAS-ASSOCIACAO (PT)

- INTROSYS-INTEGRATION FOR ROBOTIC SYSTEMS-INTEGRACAO DE SISTEMAS ROBOTICOS SA (PT)

- PANEPISTIMIO PATRON (GR)

- Hellenic Mediterranean University (GR)

- GIZELIS ROBOTICS S.A. (GR)

- Ideas Forward PC (GR)

- Rodstein Oy (FI)

- VAASAN YLIOPISTO (FI)

- UNIVERSITA DEGLI STUDI DI TORINO (IT)

- ISTITUTO P.M. SRL (IT)

- MORPHICA SOCIETA A RESPONSABILITA LIMITATA SEMPLIFICATA A SOCIO UNICO (IT)

- STMICROELECTRONICS GRENOBLE 2 SAS (FR)

- STMICROELECTRONICS ROUSSET SAS (FR)

- FUNDACION CIDAUT (SP)

- POLEVS sp. z o.o. (PL)

- THINKSTEP AG (DE)

- BELGISCH INSTITUUT VOOR LASTECHNIEK VZW (BE)

- SCUOLA UNIVERSITARIA PROFESSIONALE DELLA SVIZZERA ITALIANA (CH)

- MASSIVIT 3D PRINTING TECHNOLOGIES LTD (IL)

Results

Experimental research

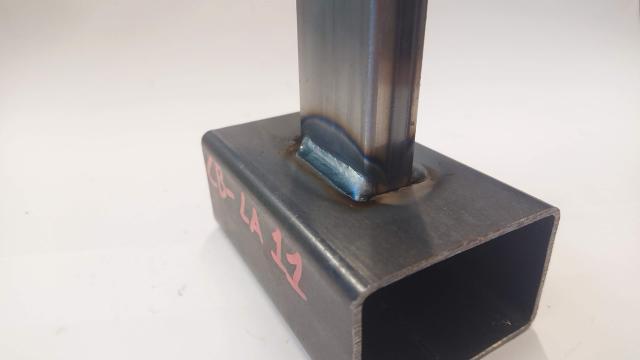

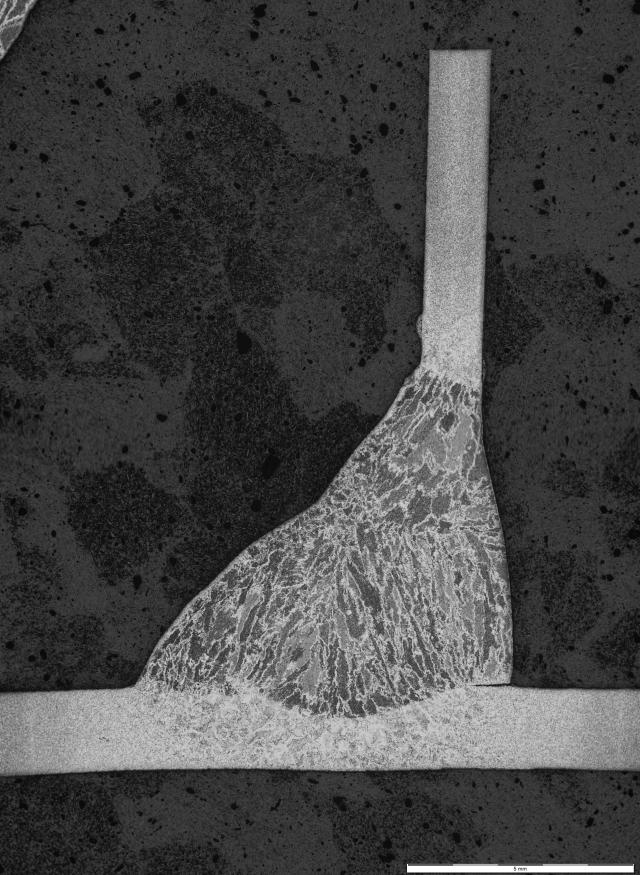

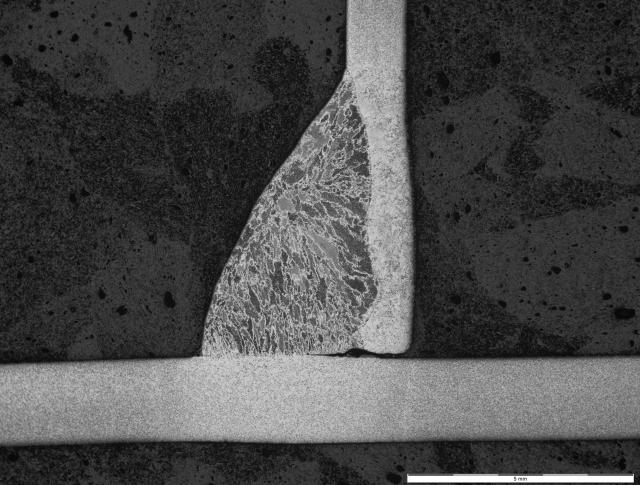

During the AVANGARD project, experiments were carried out for monitoring robotic MIG/MAG welding based on acoustic emissions. Different types of sensors were used; piezoelectric sensors and a microphone. The welding experiments were carried out for fillet welds (see Figure 2).

Figure 2: Fillet weld, part of the frame of an electric vehicle

Welds were performed with the different parameter settings of the welding process. Welds performed with optimal parameters served as a reference. In addition, welds were also performed where a particular parameter was varied; for example, the welding speed, projection length, torch position or angle and the welding direction (pulling or pushing), with the aim of introducing welding defects. The cobot used for the experimental work is a Universal Robotics UR10 with a MIGATRONICS Sigma Select 400 power source; see Figure 3).

Figure 3 : Test setup used for fillet welds

The standard ISO 5817 [Welding - Fusion welded joints in steel, nickel, titanium and their alloys - Quality levels for imperfections] was used to assess the weld quality. This international standard details the quality levels for imperfections in fusion welded joints in steels, such as cracks, porosities and voids, solid inclusions, lack of penetration and incomplete penetration, form imperfections and multiple imperfections.

|

|

Figure 4: Example of a good weld (left) and a weld with imperfections (right)

Application of artificial intelligence methods for monitoring weld quality

Artificial Intelligence offers huge potential for analysing measurement data and monitoring the quality of welds and welded products. Data-driven AI models were developed by the firm OQTON, and used to predict weld quality and recognise and classify occurring imperfections based on the noise produced by a weld. Welding voltage and current were also used for analysis through the AI models.

The observed acoustic spectrum could make a statement about the type of weld imperfection present in the weld and where in the weld this imperfection occurs. With the AI models, it is also possible to predict whether a certain weld imperfection is acceptable or not according to EN ISO 5817 (quality level C).

In this way, it is not only possible to detect welding imperfections in real time, but also immediately assign a rating to them based on the emitted acoustic spectrum. If the welding imperfection is not acceptable, it is possible in continuous installations (e.g. robotic installations) to have the system react adaptively based on this data by adjusting the welding parameters.

Deliverables

Newsletters

Publications

Technical project results

Welding-related results

- Weld quality monitoring

- High Strength Steels: An Overview

- Manual, Cobot and Robot Welding? How to Make the Choice?

- Comparison of Cobot and Manual Welding Based on Arc Parameters

- New Strategy to Evaluate Specific and Complex Welds Application Using EN ISO 5817 Standard

Other results

- Robust Additive Manufacturing Performance through a Control Oriented Digital Twin

- On the generation of validated manufacturing process optimization and control schemes

- A three-stage quality diagnosis platform for laser-based manufacturing processes