FlowCurve: Optimising mechanical joining of multi-materials

Optimising mechanical joining of multi-materials

The structural integrity of mechanical joining of materials with a limited ductility was researched during the completed research project "MechJoin". Such joining includes process-induced defects such as small cracks that can be devastating for mechanical performance. The effects of process-induced defects were studied during clinching and self-piercing riveting in this project using numeric models and experiments.

- You can find more information about this research here.

Context

Within the industry, there is an evolution towards the fabrication of products with a lighter weight, more functionality and a better performance. Hybrid parts that sometimes consist of very different materials can provide solutions for this. A multi-material design uses the material with the optimum properties for each part. The application of this is, however, being discouraged due to challenges in the area of joining technology. Different combinations in the area of materials and thicknesses make joining robustly more and more complex.

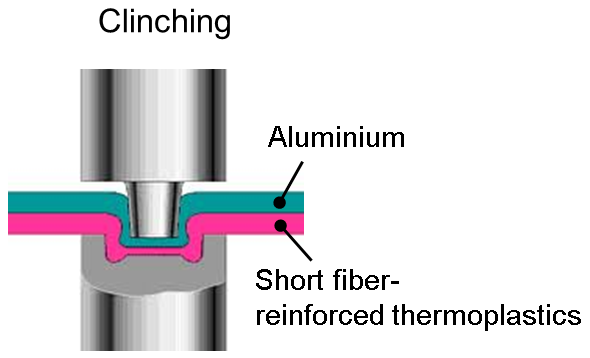

Mechanical joining techniques such as clinching or riveting allow us to join dissimilar materials; not just dissimilar metals, but also the joining of metals and other materials is possible (for example, composites).

Project goals

The BWI and KU Leuven are carrying out research into the mechanical joining of dissimilar materials: feasibility studies, testing techniques, mechanical properties, case studies, etc.

Selecting, simulating and optimising mechanical joining in a multi-material context set high requirements in relation to current material tests. Currently, no guidelines are available with regard to material characterisation for the support of the design of mechanical joining to achieve hybrid components.

One of the objectives of this project is to standardise this. Which material tests must be performed for the characterisation of mechanical joining of dissimilar materials will be determined. An investigation will be performed regarding how existing testing methods must be changed based on the new requirements.

A number of representative case studies (demonstration pieces) will also be worked out during the project based on the input of participating companies.

Clinching

Riveting