ARCLASER: Hybrid laser welding

From the industry, an increasing demand for the use of innovative and automated joining processes is observed, because of increasing quality requirements, an increased productivity and the need to reduce production costs.

In that respect, laser welding is becoming more important in modern industry, as for instance in the automotive sector, which plays a leading role with regard to application of this process in production. Recently, custom laser welding processes are available. These are the so-called "hybrid" laser welding processes, where the technology of laser welding is combined with conventional arc welding, for example MIG/MAG-welding (which is also mostly in practice). This is shown in the figure below.

ARCLASER

The project "ARCLASER" is aimed at the introduction and development in companies of the modern welding technology of hybrid laser welding (Hybrid Laser Welding – HLW), applied to various metals.

In fact, by application of HLW, the advantages of the individual welding processes (more specific laser beam welding and arc welding) are combined, while the respective disadvantages are avoided. HLW allows welding with a high welding speed (> 1 m/min), a high penetration and a low heat input (narrow heat-affected zone). At the same time, filler material is added in the weld pool in a controlled manner, which imposes less stringent demands for the weld preparation (which saves time and costs), and also allows to influence the chemical composition of the deposited material. This way of working results in a higher quality assurance, and thus to a reduction of the costs related to quality.

Project goals

The research centres CEWAC and BWI have studied this very innovative welding technology, with the aim of demonstrating the potential benefits for the industry. The main objective of this project was to provide Walloon companies access to this technology. Its potential was demonstrated for their current or future products, by the realization of demonstration workpieces in diverse materials (mainly structural steel, stainless steel, high-strength steel and aluminium alloys). The participating companies obtained an objective overview, both technically and economically, concerning the use of the hybrid laser welding technology, its benefits and the parameters related to production. The focus of the research was mainly put on the weld quality, the productivity and the robustness of the process.

As also the case for conventional laser welding, hybrid laser welding represents a considerable investment cost for a company, and especially for an SME. This cost should of course be justified based on a technological and economical comparison with other current joining techniques.

The partners generated knowledge and information about this by objective research. Knowledge dissemination and valorisation of the high-tech expertise obtained by the research centres in this project are insured by the respective teams of technological consultants.

The goal of ARCLASER is to provide information about HLW, applied to various metals used in production of the companies involved, both on qualitative level (welding quality, weld characterisation) and quantitative level (productivity, production costs), through the development of demonstration workpieces.

In this way, the results of this project and the acquired knowledge led to the introduction and further development of hybrid laser welding in Walloon companies.

Project description

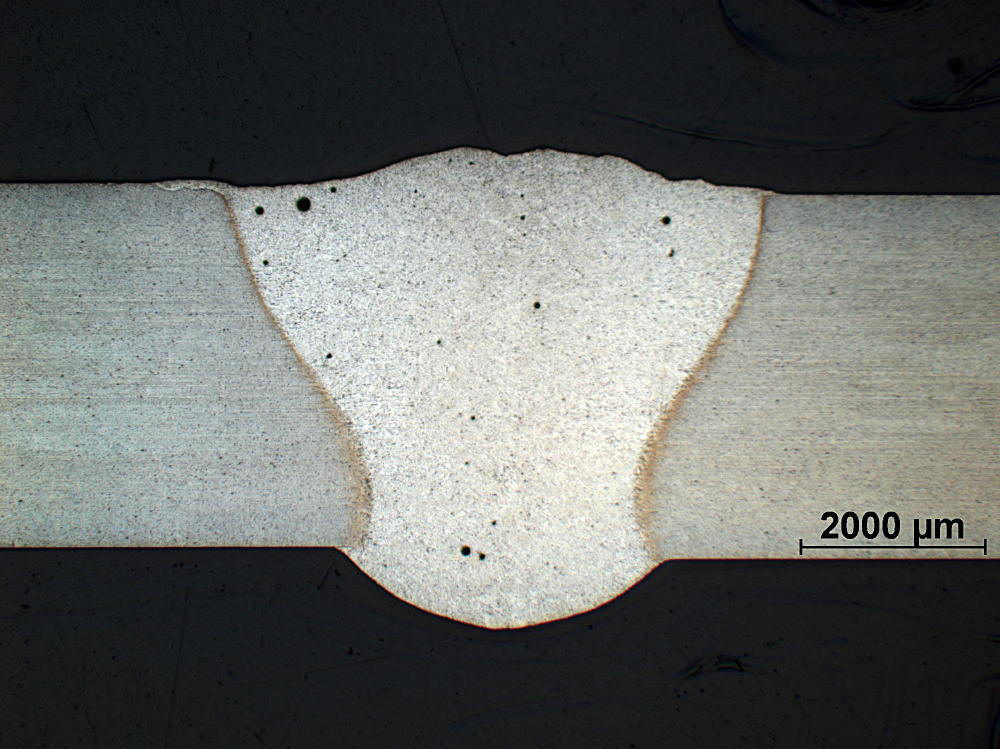

Listed below are some metallographic sections of joints with HLW during earlier projects coordinated by BWI.

|

4 mm 6082-T6 aluminium alloy 1,6 mm DP600 steel welded with HLW at 4 m/min |

12 mm AISI 321 stainless steel welded with HLW in one pass at 2 m/min |

Contact

Companies that have an interest in this technique or wish to investigate the applicability for a possible application, can contact:

ir. Fleur Maas

Research Centre of the BWI

E-mail : Fleur Maas

Tel. : +32 (0)9 292 14 02