Tensile test

In order to verify the (required) mechanical properties of a material, a tensile test can be performed. The test specimen will be subjected to a slowly increasing tensile force until fracture occurs.

After completion of the test, it is possible to determine various mechanical properties of the material, like:

Tensile tests on base material

- Elongation after fracture, A (%)

- Reduction of area, Z (%)

- Tensile strength, Rm (MPa)

- Yield or proof strength, Re and Rp (MPa)

- Modulus of elasticity, E (GPa)

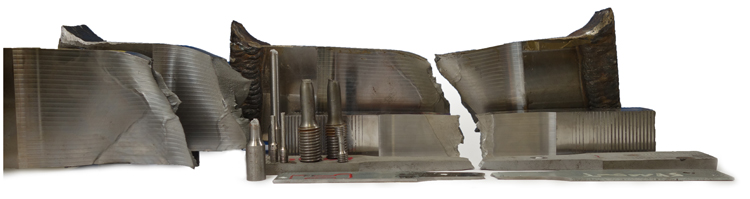

Tensile tests on welded joints

- Tensile strength, Rm (MPa)

- Fracture location

- Base material

- Welded material

- Heat Affected Zone (HAZ)

Applications

- Material characterization and verification

- Welding procedure qualification (e.g. according to EN ISO 15614)

- Characterization of the mechanical properties at low- or elevated temperature (-196°C up to 1000°C)

Test standards

- EN ISO 6892-1: Tensile testing at room temperature

- EN ISO 6892-2: Tensile testing at elevated temperature

- EN ISO 6892-3: Tensile testing at low temperature

- EN ISO 5178: Longitudinal tensile test on weld metal in fusion welded joints

- EN ISO 4136: Transverse tensile test of welded joints

- EN ISO 10164: Determination of the through tickness properties (Z-quality)

If testing has to be performed according to any other test standard (e.g. ASME, AWS, ASTM,...) listed above, please do not hesitate to contact us!

- ASTM A370

- ASTM E8

- ASTM E119

- ASTM F606

- ANSI/AWS B4.0

- ...