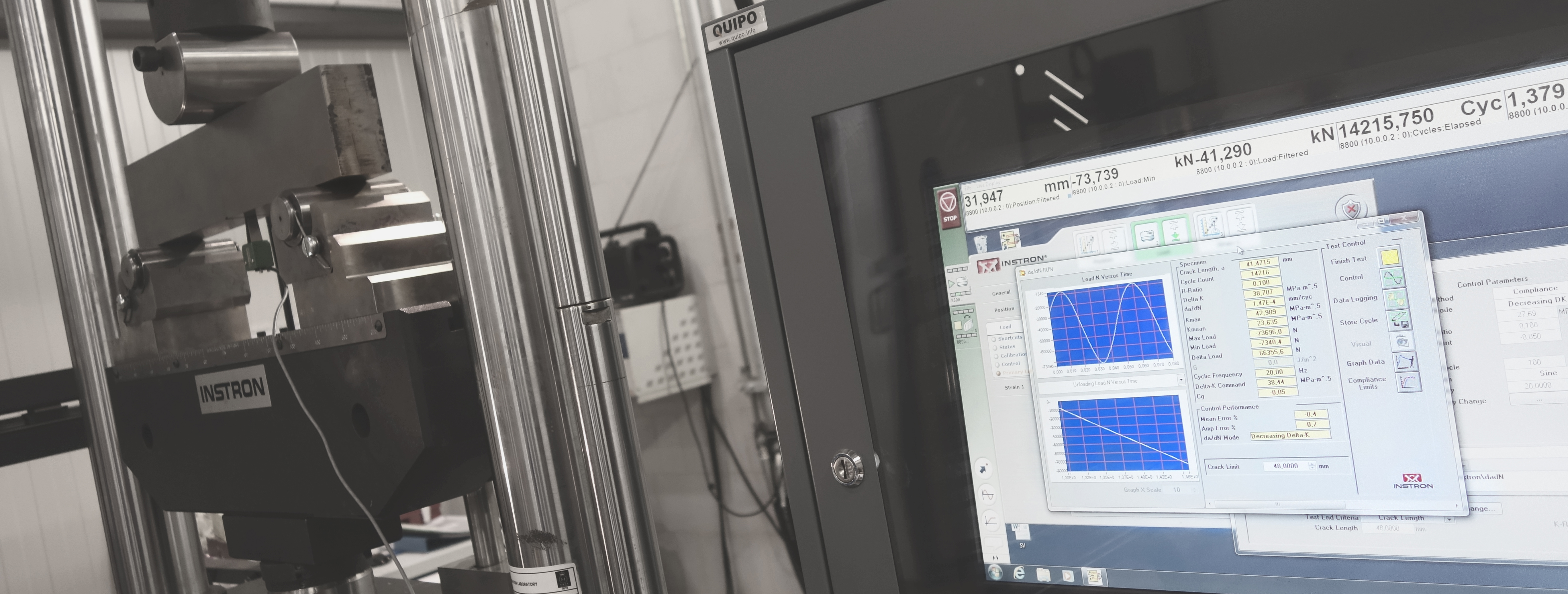

Corrosion fatigue testing

A Fitness For Service assessment determines when a structure can safely be or remain in service. Fracture mechanics tests can be used to predict the service life of a structure and establish criteria that the material must meet, or an inspection plan can be composed when a crack is present in the structure. For example, material for railway applications must meet criteria listed in EN 13647.

To support these assessments, BWI can conduct fatigue tests in accordance with the standards below where crack propagation ("Fatigue Crack Growth Rate") may or may not be followed.

Both bending test specimens (SENB) and compact tension (CT) test specimens can be tested.

As input for fracture-mechanical calculations, it is important that the material properties are determined under operating conditions or approach the operating conditions as faithfully as possible. On request, fatigue tests in a corrosive environment, such as seawater, can also be carried out.

Testing standards

- ISO 1099 – Fatigue testing – Axial force-controlled method (ASTM E466)

- ASTM E466 - Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

- DIN 50100 - Load controlled fatigue testing – Execution and evaluation of cyclic tests at constant load amplitudes on metallic specimens and components

- ISO 12108 – Fatigue testing – Fatigue crack growth method (ASTM E647)

- ASTM E647 - Standard Test Method for Measurement of Fatigue Crack Growth Rates

- EN ISO 11782-2 - Corrosion fatigue testing – Crack propagation testing